Concrete Curing: The Key to Job Site Safety

Hold on, folks! Today, we’re diving deep into the world of concrete curing, and trust me, it’s not just about making sure your sidewalk looks pretty. Nope, this is all about keeping you and your crew safe on the job site. So, grab a cup of coffee (or maybe a hard hat), and let’s explore why proper concrete curing is the unsung hero of construction site safety.

The Perils of Uncured Concrete

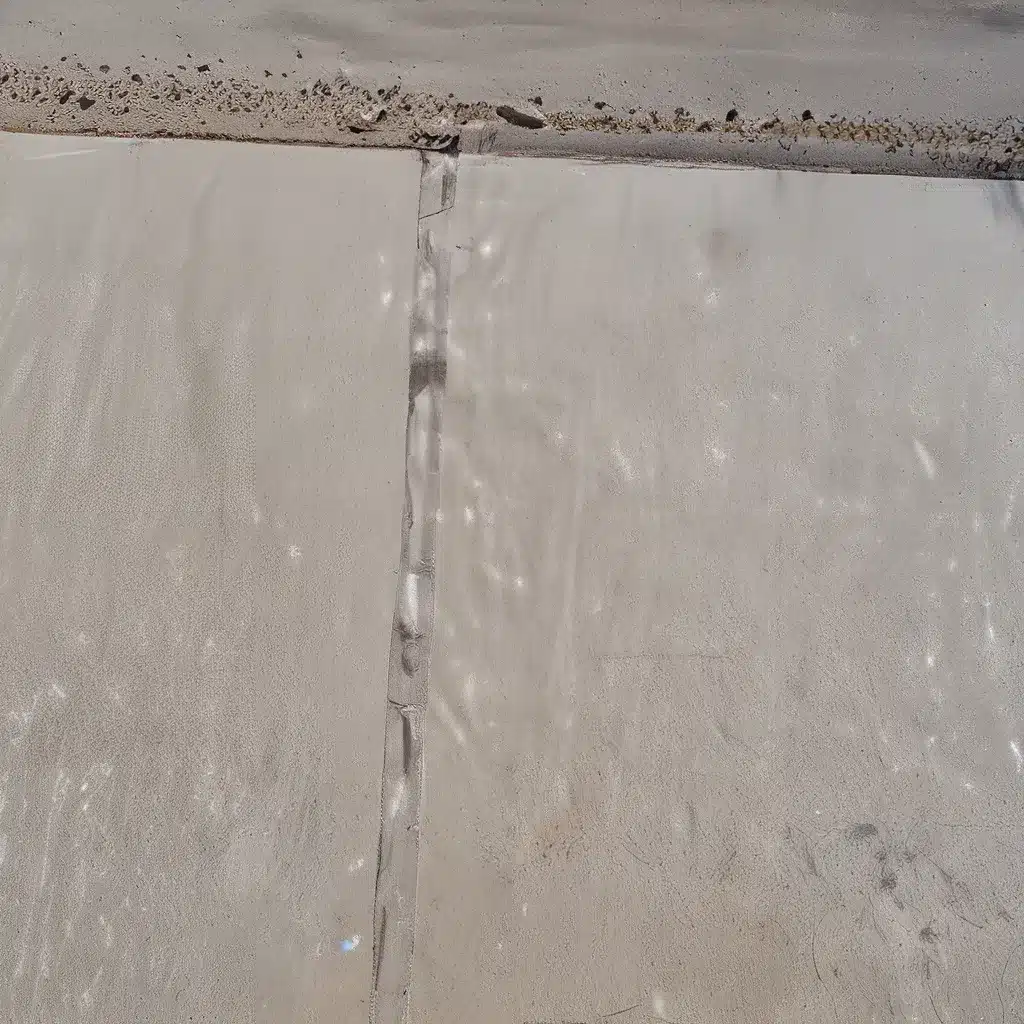

Imagine this scenario: You’re on the job, happily mixing and pouring that fresh, silky-smooth concrete, thinking everything is sunshine and rainbows. But wait, what’s that you see? Cracks? Crumbling edges? Yikes, Houston, we have a problem!

Uncured concrete can be a ticking time bomb, just waiting to unleash its wrath on unsuspecting workers. Think about it – that delicate balance of water, cement, and aggregates needs time to fully harden and develop its strength. If you rush the process or skimp on the curing, you’re setting yourself up for a world of trouble.

Curing: The Key to Concrete’s Strength

Alright, let’s get down to the nitty-gritty. Proper curing is absolutely essential for concrete to reach its full potential. It’s like a well-tended garden – you’ve got to give it the right amount of water, sun, and TLC for those plants to really thrive. The same goes for concrete.

According to the experts at the Portland Cement Association, curing helps maintain the desired moisture and temperature conditions in the concrete, allowing it to properly hydrate and develop strength over time. This, in turn, leads to better volume stability, resistance to freezing and thawing, and overall durability.

In other words, if you skimp on the curing, you’re essentially building a house of cards – it might look good at first, but the slightest gust of wind (or, in this case, a heavy load) can bring the whole thing crashing down. And trust me, you don’t want to be anywhere near when that happens.

The Curing Countdown: Timing is Everything

Alright, now that we’ve established the importance of curing, let’s talk about the nitty-gritty details. How long should you be curing that concrete, you ask? Well, it depends.

According to the American Concrete Institute (ACI), the minimum curing period for slabs, pavements, and other structural concrete is typically seven days, as long as the ambient temperature is above 40 degrees Fahrenheit. But wait, there’s more! The ACI also recommends that the curing period should continue until the concrete reaches at least 70% of its specified compressive strength.

Now, you might be thinking, “But wait, what if the weather’s not cooperating?” Well, fear not, my friends! The experts have got your back. ACI has recommendations for curing in both cold and hot weather to ensure that the concrete reaches its full potential, no matter what Mother Nature throws your way.

Curing Methods: Keeping Concrete Cozy and Hydrated

Alright, so we know the importance of curing and the recommended timelines, but how do we actually make sure that concrete stays, well, cured? Fear not, there are plenty of tried-and-true methods to keep that concrete happy and healthy.

Ponding and Immersion: These methods involve keeping the concrete surface submerged in water or covered with a continuous water layer. Perfect for those flat surfaces, but be careful not to let the water get too cold and cause thermal stress.

Spraying and Fogging: When the temperatures are above freezing and the humidity is low, a good old-fashioned misting can work wonders to prevent that pesky plastic shrinkage cracking.

Wet Coverings: Once the concrete has had a chance to harden up a bit, you can throw some saturated burlap or other wet coverings over the surface to keep that moisture locked in.

Curing Compounds: These membrane-forming magicians can help reduce evaporation and lock in that precious H2O. Just be sure to apply them as soon as that final finishing is done.

Heat and Steam: For those hardcore concrete enthusiasts, there’s always the option of live steam or heating coils to really kick that curing process into high gear. Just be careful not to overdo it and cause more problems than you solve.

The Safety Factor: Why Curing Matters

Alright, enough with the technical jargon – let’s talk about the real reason we’re all here: safety. You see, that properly cured concrete isn’t just about aesthetics or strength; it’s the foundation (pun intended) of a safe job site.

As our friends at Suzio York Hill explain, inadequately cured concrete can lead to a whole host of hazards, from slip and fall risks to crumbling structures that could put your crew in harm’s way. And let’s not forget the potential for chemical burns from that nasty, alkaline wet concrete – yikes!

But fear not, my friends! When you take the time to properly cure that concrete, you’re not just creating a sturdy, long-lasting structure; you’re also ensuring the safety of everyone on the job site. It’s a win-win situation, if you ask me.

The Concrete Curing Checklist: Keeping Your Crew Safe

Alright, let’s recap the key concrete curing tips to keep your job site safe and sound:

-

Proper PPE: Make sure your crew is decked out in the right gear, from safety glasses and gloves to waterproof boots and kneepads. Concrete may seem harmless, but it can do a number on your skin and eyes if you’re not careful.

-

Lifting Techniques: Teach your team the proper way to lift those heavy bags and buckets of concrete. Bending those knees and keeping those backs straight can go a long way in preventing injuries.

-

Curing Vigilance: Keep a close eye on that concrete, making sure it’s getting the moisture, temperature, and protection it needs during the curing process. Remember, time is of the essence!

-

Slip and Trip Prevention: Stay on top of those spills and keep the work area tidy to avoid any slips, trips, or falls. Safety first, folks!

-

Communication is Key: Make sure everyone on the job site is on the same page, using hand signals or radios to coordinate movements and activities, especially when dealing with heavy machinery.

By following these simple steps, you can rest assured that your crew will be safe, sound, and ready to tackle the next concrete-related challenge that comes their way. After all, a happy and healthy team is the foundation of any successful construction project.

The Concrete Curing Conundrum: Mastering the Balancing Act

Now, I know what you’re thinking – with all these curing requirements and safety concerns, it must be a real headache to keep everything in order, right? Well, you’re not wrong. Concrete curing is kind of like a delicate balancing act, where you’ve got to juggle temperature, moisture, and time all while keeping your crew out of harm’s way.

But fear not, my friends! The experts at Concrete R Us are here to help. We’ve got a team of seasoned professionals who know the ins and outs of concrete curing, and we’re dedicated to making sure your job site is as safe as can be.

Whether it’s recommending the right curing methods for your project, helping you develop a comprehensive safety plan, or providing the high-quality concrete you need to get the job done right, we’ve got your back. So, the next time you’re stressing about the curing conundrum, just remember – Concrete R Us is here to help you master the balancing act and keep your crew safe, sound, and ready to tackle the next big challenge.