Reinventing Construction: A Route to Higher Productivity

Now, I don’t know about you, but when I hear the words “construction” and “productivity” in the same sentence, my mind immediately conjures up images of endless delays, cost overruns, and disgruntled project managers tearing their hair out. It’s a problem that has plagued the industry for decades, and the folks over at the McKinsey Global Institute have the data to prove it.

According to their recent report, “Reinventing Construction: A Route to Higher Productivity,” the construction industry has been stuck in a proverbial time warp, with global labor-productivity growth averaging a meager 1% per year over the past two decades. That’s a stark contrast to the 2.8% growth seen across the total world economy and the 3.6% jump in manufacturing. Yikes!

So, what’s the deal? Why is the construction industry lagging so far behind, and what can be done to turn things around? Well, the McKinsey team has identified a few key culprits, including stringent regulations, industry fragmentation, and a general lack of investment in skills development, R&D, and innovation. But the good news is that change is not only possible, but it’s already happening in pockets across the industry.

Embracing Disruption: The Path to Productivity

As I was digging into this topic, I couldn’t help but wonder: what does it take to disrupt an industry that’s been stuck in its ways for so long? Well, it turns out that the construction industry is ripe for a shakeup, and the organizations that are leading the charge are taking a multifaceted approach to tackling the productivity challenge.

Some are opting for a more incremental approach, establishing small, discrete programs to adopt best practices. Others are going for a more transformational agenda, working within the current confines of the industry to drive change. And then there are the real mavericks, making strategic bets to radically restructure the value chain or establish manufacturing-like systems of mass production.

Now, I don’t know about you, but the idea of bringing a little automotive-style assembly line magic to the world of concrete and steel has got me intrigued. After all, if it worked for Henry Ford, why can’t it work for the construction titans of tomorrow?

Concrete Conundrums and Collaborative Solutions

As I delved deeper into the world of commercial concreting, I couldn’t help but notice that the challenges facing this industry are not unlike the broader productivity woes plaguing construction as a whole. From stringent regulations to industry fragmentation, the obstacles can seem daunting, but the folks at Structural Systems Repair Group (SSRG) are proving that with the right mindset and approach, it’s possible to not just overcome these hurdles, but to thrive in the process.

At SSRG, they’ve taken a page out of the McKinsey playbook, embracing a collaborative, problem-solving mindset that sets them apart from the traditional, adversarial contractor-client dynamic. By aligning their interests with their clients and focusing on well-defined outcomes, they’re able to deliver projects that meet schedule and cost targets, all while maintaining the highest standards of quality and safety.

But it’s not just about the contractual framework; SSRG is also leading the charge when it comes to rethinking the design and engineering process. By institutionalizing value engineering and pushing for more repeatable design elements, they’re able to drive efficiency and consistency across their projects, without sacrificing the unique needs of each client.

Mastering the Art of On-Site Execution

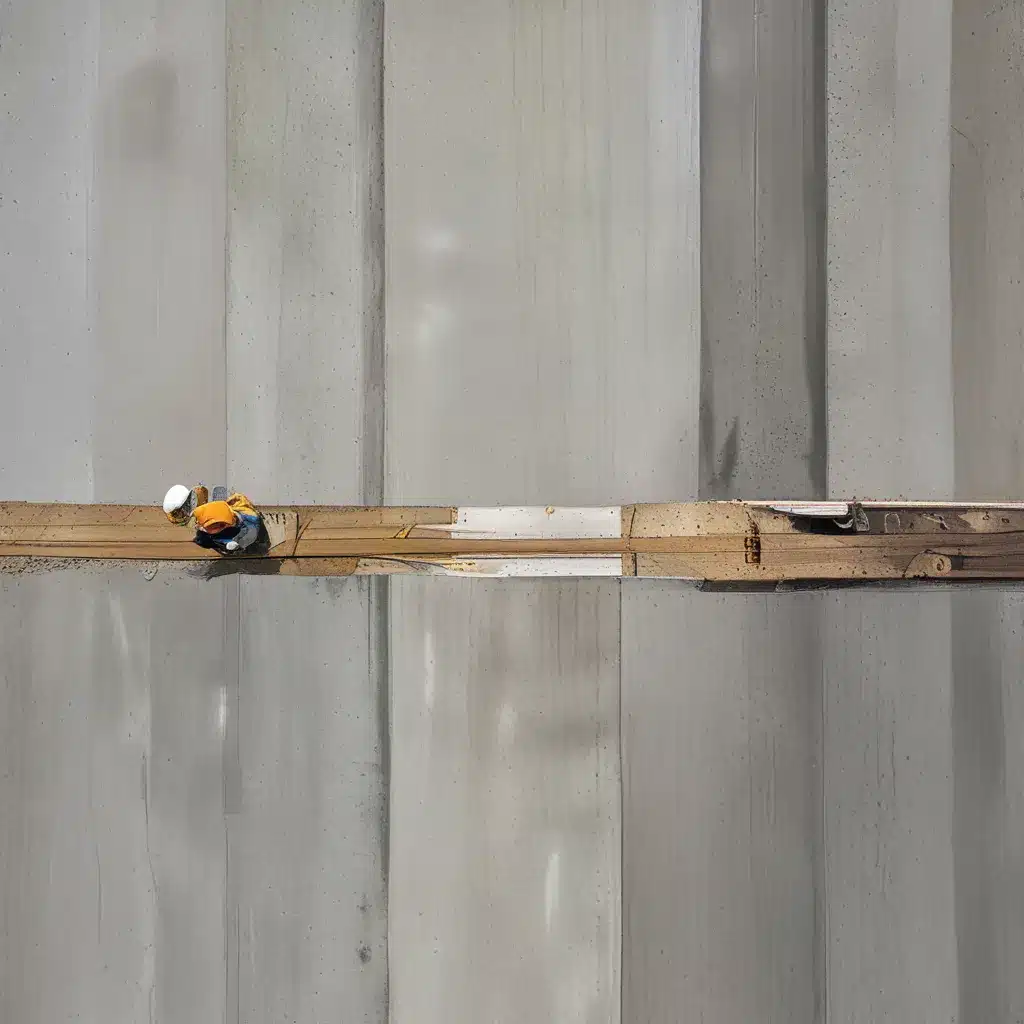

Of course, even the best-laid plans are nothing without flawless on-site execution, and that’s an area where SSRG really shines. They’ve honed their process to a fine art, implementing a rigorous planning regimen to ensure that activities are achieved on time and on budget, and they’re not afraid to get their hands dirty when it comes to managing the nitty-gritty details.

But it’s not just about the technical systems; SSRG also understands the importance of getting the human element right. They’ve invested heavily in developing their workforce, championing apprenticeship programs and collaborating with local workforce boards to ensure that their teams are equipped with the skills and knowledge they need to thrive in the ever-evolving world of commercial concreting.

And let’s not forget about the digital revolution that’s sweeping through the industry. SSRG is at the forefront of this transformation, embracing cutting-edge technologies like 5D building information modeling and advanced analytics to optimize their workflows and drive even greater productivity gains.

Embracing the Future of Commercial Concreting

As I reflect on my journey through the world of commercial concreting, I can’t help but be inspired by the ingenuity and resilience of the industry leaders like SSRG. They’re proving that with the right mindset, the right approach, and the right tools, it’s possible to overcome even the most daunting productivity challenges and deliver world-class results for their clients.

So, if you’re a business or municipality looking to tackle your next big infrastructure project, I’d highly recommend checking out Concrete Townsville and the team at SSRG. They’re not just experts in the art of commercial concreting; they’re pioneers in the quest to reinvent the industry and usher in a new era of productivity and innovation.

Who knows, maybe with a little bit of that SSRG magic, we can turn construction from a perennial productivity problem into the world’s next great productivity story. After all, as the McKinsey team says, the pressure to act is rising, the demand is soaring, and the time for change is now. So, let’s roll up our sleeves, get to work, and show the world what the future of commercial concreting looks like.