Ah, the wonderful world of concrete – that sturdy, reliable material that forms the foundation of our built environment. But let me tell you, this stuff is like a diva, needing just the right amount of attention and care to truly shine. And when it comes to the curing process, well, that’s where the real drama unfolds.

Understanding the Concrete Curing Process

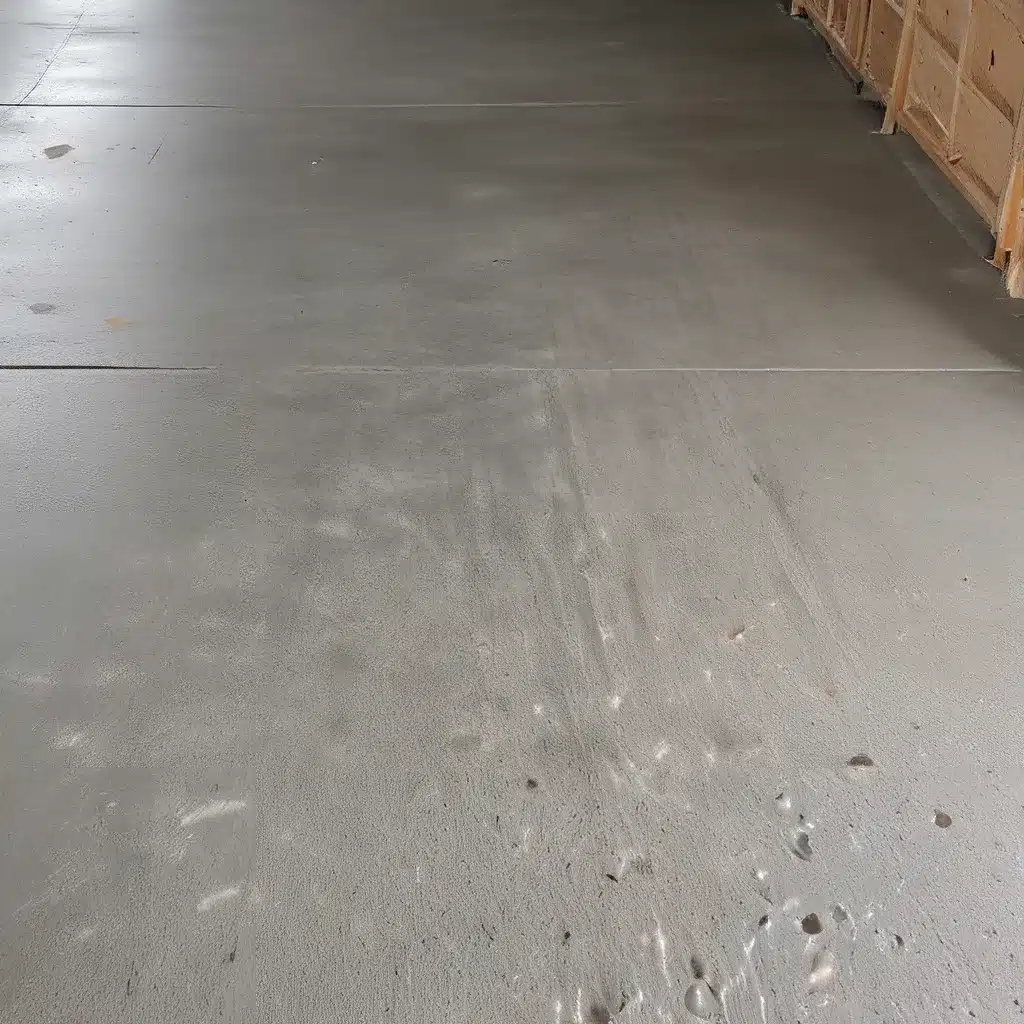

You see, when that fresh concrete is poured, it’s like a newborn babe – delicate, sensitive, and easily ruined if not properly tended to. The first week or so after it’s laid is a crucial time, where the temperature and moisture levels need to be just right to allow for proper curing. Neglect this step, and you’ll be sorry – your concrete could end up with a pattern of fine cracks, low strength, and a surface that’s practically begging to be resurfaced.

Now, the entire curing period for concrete takes about a month, but the good news is, it’ll be ready for use much sooner than that. The exact timeline can vary depending on factors like the weather, the concrete mix, and the finishing techniques used. But as a general rule of thumb, you can start using that new slab after just a week or so.

According to the experts at The Concrete Network, the key to successful curing is all about maintaining the right moisture and temperature conditions. It’s like raising a finicky teenager – you’ve got to give them just the right amount of attention and care, or they’ll turn into a total train wreck.

The Three Phases of Curing

Now, the curing process can be broken down into three distinct phases, and the length of each one depends on the specific concrete and environmental conditions. Let’s dive in, shall we?

Phase 1: Initial Set

During this first phase, it’s all about managing the rate at which the concrete’s “bleed water” (that’s the excess water that comes to the surface) evaporates. If that evaporation happens too quickly, you’re looking at some serious trouble – think fine cracks, dusting, and low surface strength. To prevent this, you can use techniques like fogging, spraying, or applying an evaporation retardant. Just think of it as giving your baby concrete a nice little mist to keep its delicate skin hydrated.

Phase 2: Ongoing Curing

Once the initial set is done, the concrete surface still needs moisture and attention. This is where you really need to make sure you’re curing that concrete properly. You can’t just assume it’ll take care of itself – oh no, this is where you need to be vigilant, using methods like ponding, wet coverings, or curing compounds to keep that moisture locked in. Trust me, you don’t want your perfect little concrete to turn into a juvenile delinquent.

Phase 3: Temperature Control

And let’s not forget about temperature – that’s a crucial factor in the curing process. Concrete can be a real diva when it comes to temperature extremes. If it gets too cold, the hydration reaction slows down to a crawl, and if it gets too hot, the reaction happens too quickly, leading to all sorts of cracking and strength issues. That’s why it’s important to keep that concrete temperature between a nice, cozy 50-85 degrees Fahrenheit. It’s like Goldilocks – not too hot, not too cold, but juuust right.

Curing Techniques for Colored Concrete

Now, when it comes to colored concrete, the curing process gets a bit more, shall we say, glamorous. See, with regular old gray concrete, appearance isn’t really a big concern. But with colored concrete, whether it’s integral or dry-shake, the way it looks is everything. And that means the curing techniques need to be a little more, well, tailored.

According to the experts at the Portland Cement Association, the best approach for decorative concrete is to try to alter the conditions so you don’t even need to do that initial curing. Block the wind, keep the sun off the concrete, and get that mix nice and cool before pouring. If that’s not possible, you can try a little fogging just to keep the surface damp, or use an evaporation retardant to create a protective membrane.

And remember, those desirable properties of concrete – strength, durability, resistance to cracking and abrasion – they’re all improved by proper curing. So don’t skimp on this step, my friends. Your concrete is counting on you to be its fairy godmother and give it the royal treatment it deserves.

Curing Times and Concrete Strength

Now, let’s talk about the all-important question of how long it takes for concrete to fully cure. Well, the answer, as you might have guessed, is that it depends. The minimum curing period is generally seven days for ambient temperatures above 40 degrees Fahrenheit, but that’s just the bare minimum. According to the American Concrete Institute (ACI), the recommended curing period is the time it takes for the concrete to reach 70% of its specified compressive strength.

And let me tell you, that 70% mark can be reached a whole lot sooner if the concrete is curing at higher temperatures or if certain cement-admixture combinations are used. On the flip side, if the temperatures are lower, it might take a bit longer. It’s like that old saying – the Goldilocks principle applies to concrete curing too.

But the good news is, even if you can’t give your concrete the full recommended curing time, you’re still in pretty good shape. According to The Concrete Network, concrete that’s moist-cured for just 3 days can still achieve about 80% of the benefits of 7-day water curing. So if you’re on a tight schedule, you can still get your project looking and performing its best.

Curing in Extreme Conditions

Of course, we can’t forget about those extreme weather conditions that can really throw a wrench in the curing process. When the mercury starts to plummet or soar, you’ve got to bring in the big guns.

According to the Portland Cement Association, in cold weather, you might need to use heated enclosures, curing compounds, or insulating blankets to keep that concrete at a toasty 50 degrees Fahrenheit or above. And in hot weather, you’ll want to focus on minimizing moisture loss with things like sunscreens, fogging, and evaporation retardants. It’s like a high-stakes game of “Goldilocks and the Three Bears” – except the stakes are the integrity of your concrete.

But don’t worry, my friends at Concrete R Us have got your back. They’ve been in the concrete game for over 50 years, and they know all the tricks of the trade when it comes to curing in even the most extreme conditions. So if you’re ever feeling unsure about how to keep your concrete happy and healthy, just give them a call – they’ll have you covered, no matter what Mother Nature throws your way.

Wrapping it Up

Whew, that’s a lot of information to take in, I know. But the bottom line is this: when it comes to concrete, curing is everything. It’s the difference between a strong, reliable surface and a cracked, dusting mess. And whether you’re dealing with a simple slab or a decorative masterpiece, the principles are the same – maintain that moisture, control the temperature, and give your concrete the TLC it deserves.

So the next time you’re planning a concrete project, remember: this stuff is like a delicate flower, needing just the right conditions to bloom into its full, glorious potential. And with a little bit of know-how and a whole lot of patience, you can help that concrete diva shine brighter than ever before. Happy curing, my friends!