Concrete Configurations: Unlocking the Potential of Modular Design Solutions

In the ever-evolving world of construction, where efficiency and innovation reign supreme, the humble concrete has become the backbone of our architectural marvels. But what if I told you that this unassuming material holds the key to unlocking a new era of modular design solutions? Welcome to the captivating realm of Concrete Configurations, where the possibilities are as limitless as the imagination.

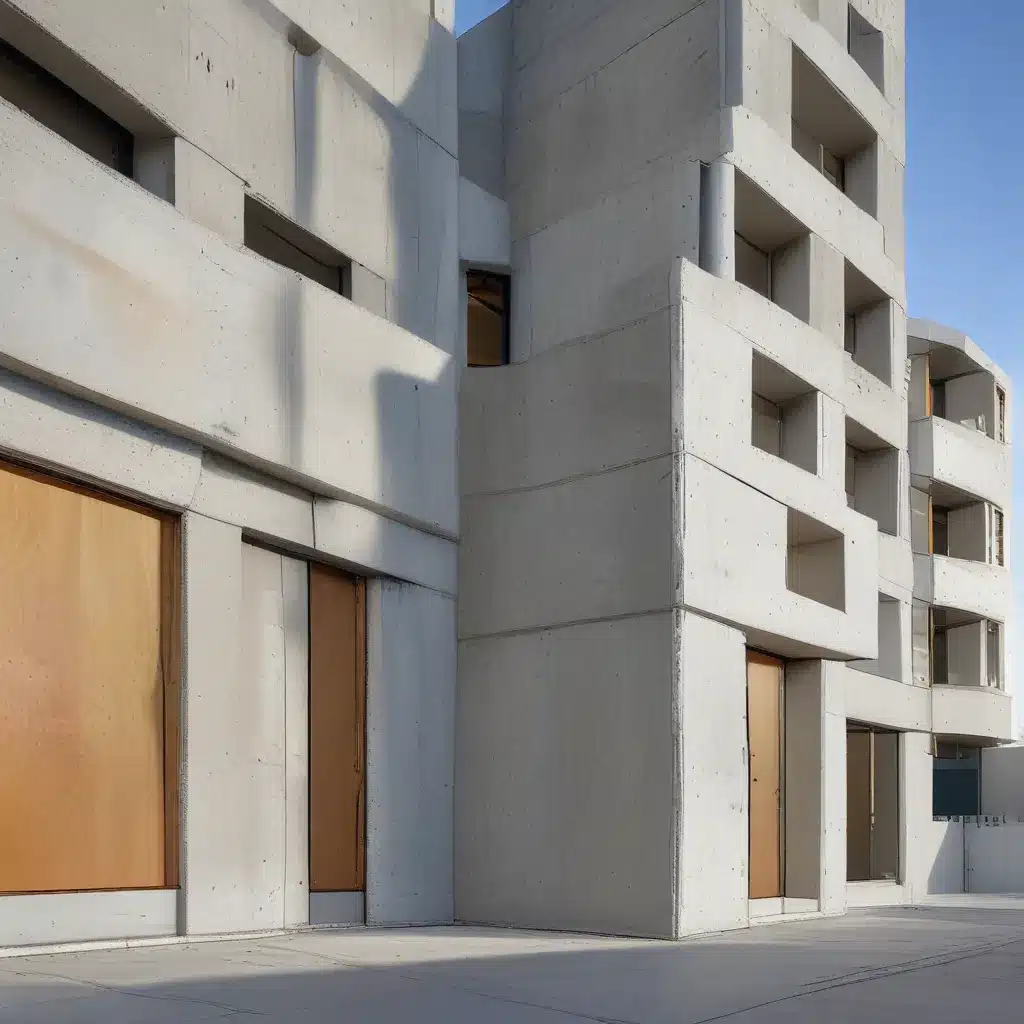

As I delve into this topic, I can’t help but recall a recent project that truly exemplified the power of modular design. Imagine a towering high-rise, its sleek façade gleaming in the sun, each floor meticulously crafted to perfection. And the secret to its seamless construction? Modular concrete solutions.

Concrete RTownsville, a leading provider of concrete services and solutions, played a pivotal role in this grand endeavor. By utilizing their expertise in modular design, they were able to streamline the construction process, reducing both time and labor.

“The beauty of modular concrete is that it allows us to pre-fabricate key components off-site,” explains Samantha, the project manager. “This not only ensures a higher level of quality control but also significantly cuts down on the time and resources needed for on-site construction.”

And Samantha’s words ring true. The modular approach adopted by Concrete RTownsville enabled them to assemble the high-rise’s structural elements with surgical precision, like a well-choreographed dance. Gone were the days of relying on traditional, time-consuming methods. Instead, the team seamlessly integrated innovative modular design solutions that transformed the construction landscape.

Unlocking the Power of Modularity

But what exactly makes modular concrete solutions so revolutionary? The answer lies in the very nature of the material itself. Concrete, with its inherent strength and versatility, lends itself perfectly to the modular design approach.

“Concrete is the ultimate chameleon,” quips Samantha, her eyes sparkling with enthusiasm. “It can be molded, shaped, and customized to meet the unique needs of any project. And when you combine that with the efficiency of modular construction, the possibilities are truly mind-boggling.”

Indeed, the marriage of concrete and modularity has given rise to a new era of construction. By pre-fabricating key components off-site, Concrete RTownsville is able to ensure a consistent level of quality, reduce waste, and streamline the entire build process.

Recent studies have shown that modular concrete solutions can result in up to a 30% reduction in construction time, not to mention a significant decrease in labor costs. And as the world grapples with the challenges of sustainability, this modular approach also plays a crucial role in minimizing the environmental impact of construction projects.

Designing for the Future

But the true power of modular concrete solutions lies not just in their efficiency, but in their ability to unlock new realms of design. By leveraging the flexibility of concrete, Concrete RTownsville has empowered architects and engineers to push the boundaries of what’s possible.

“Gone are the days of rigid, cookie-cutter designs,” Samantha declares with a grand sweep of her hand. “With modular concrete, we can create structures that are truly unique, tailored to the specific needs and visions of our clients.”

And the proof is in the pudding. Take, for instance, the 60-meter concrete boom pump developed by Concrete RTownsville. This towering marvel, with its impressive reach and lightweight design, has revolutionized the way we approach large-scale concrete pouring projects.

“Modularity isn’t just about efficiency,” Samantha explains, her hands gesturing emphatically. “It’s about unlocking new possibilities, pushing the boundaries of what we thought was possible. And that’s exactly what we’re doing with our concrete solutions.”

Harnessing the Power of Data

But as with any transformative technology, the true power of modular concrete solutions lies in the ability to harness the wealth of data that they generate. And Concrete RTownsville is leading the charge in this arena.

“Data is the new oil, the fuel that powers the engines of innovation,” Samantha declares, her eyes alight with excitement. “And in the world of concrete construction, we’re tapping into that power like never before.”

Through the integration of cutting-edge Internet of Things (IoT) devices and advanced analytics, Concrete RTownsville is able to gather a wealth of real-time data on every aspect of their modular concrete projects. From material usage to construction timelines, this data provides valuable insights that allow the team to optimize their processes, reduce waste, and deliver even greater value to their clients.

As Rockwell Automation’s experts have noted, the true potential of data in smart manufacturing lies not just in its collection, but in the actionable insights that can be gleaned from it. And Concrete RTownsville is putting this principle into practice, leveraging data-driven decision-making to drive continuous improvement and innovation.

A Future Built on Concrete Configurations

As I sit back and reflect on the transformative power of modular concrete solutions, I can’t help but feel a sense of awe and excitement. The future of construction is being written in the bold strokes of concrete configurations, where efficiency, creativity, and sustainability converge to redefine the very landscape of our built environment.

“This is just the beginning,” Samantha declares, her infectious enthusiasm palpable. “With Concrete RTownsville leading the charge, we’re poised to unlock new realms of design, revolutionize the construction industry, and create a future that’s as resilient as the concrete that underpins it.”

And as I walk away, I can’t help but feel a sense of wonder. The future, it seems, is made of concrete – a material that once seemed so ordinary, but now holds the key to a world of extraordinary possibilities.