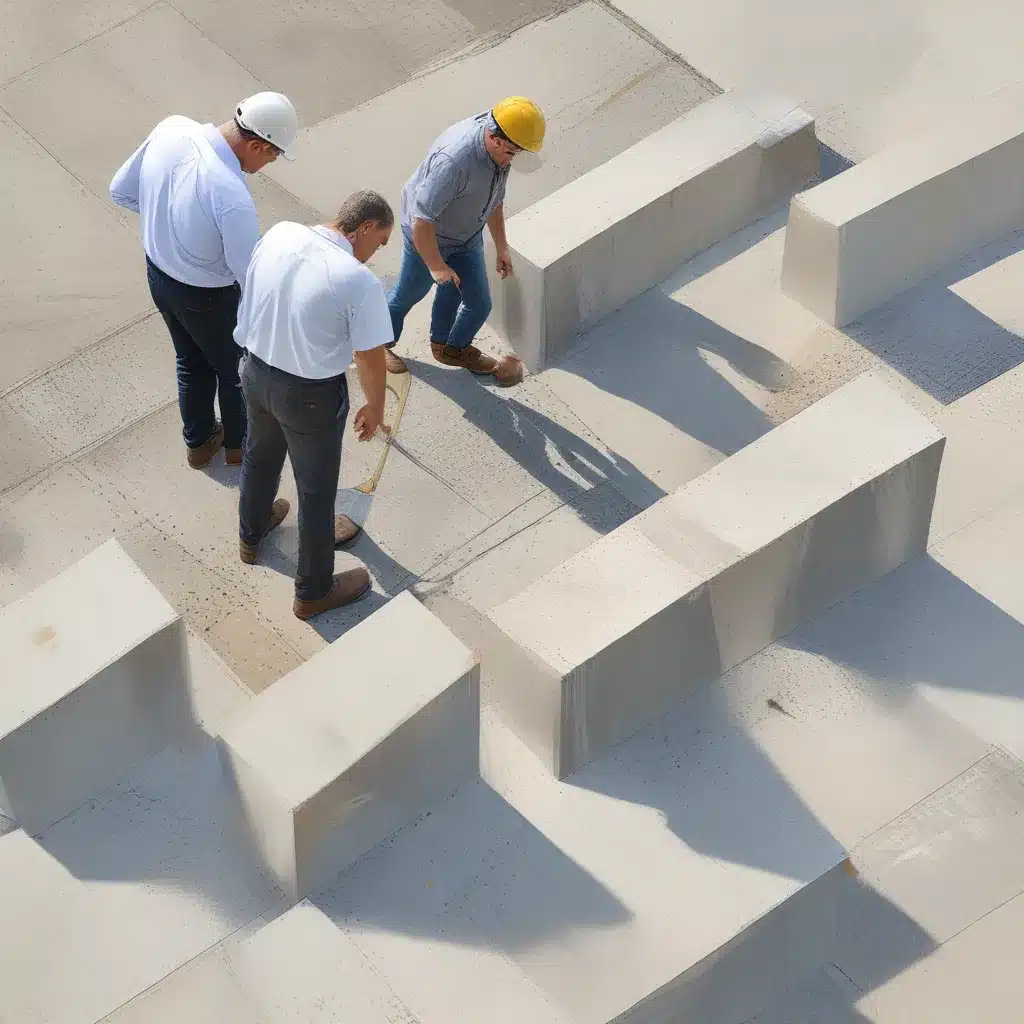

Concrete Challenges and the Art of Project Management

As a concrete solutions provider, I’ve had the privilege of working on all sorts of ambitious projects – from massive commercial high-rises to intricate residential foundations. And let me tell you, managing these kinds of concrete endeavors is no easy feat. There are so many moving parts, complex logistics, and potential pitfalls to navigate. But over the years, I’ve developed a keen eye for what it takes to master concrete projects, and I’m excited to share these insights with you today.

You see, effective project management is the secret sauce that can make or break any concrete undertaking, no matter the scale. It’s about seamlessly coordinating teams, optimizing processes, and anticipating challenges before they derail your progress. And trust me, I’ve seen my fair share of concrete calamities – from late material deliveries to unexpected weather delays. But the companies and project managers who come out on top are the ones who approach these challenges with a strategic, resilient mindset.

So, let’s dive in, shall we? In this article, we’ll explore the essential elements of mastering concrete projects, gleaned from my own experiences as well as insights from industry leaders and top business schools. Get ready to elevate your concrete game and become a project management guru in your own right!

The Importance of Project Planning in Concrete Endeavors

They say that “well-begun is half-done,” and I can’t agree more when it comes to concrete projects. The key to success lies in meticulous planning from the very start. You see, concrete work is incredibly complex, with a million moving parts to keep track of. And if you don’t have a solid blueprint in place, it’s all too easy for things to spiral out of control.

That’s why the first step in mastering concrete projects is to invest time and resources into comprehensive planning. This means mapping out every stage of the process, from material procurement and site preparation to team coordination and quality control. Concrete experts suggest breaking down your project into manageable milestones, with clear deadlines and accountability measures for each.

But it’s not just about creating a detailed schedule – you also need to anticipate potential roadblocks and have contingency plans in place. What if there’s an unexpected weather event that delays your pour? Or a key piece of equipment breaks down at the last minute? By thinking through these scenarios ahead of time, you can minimize the impact on your timeline and budget.

I’ll never forget the time we were working on a massive commercial project, and a critical concrete delivery got stuck in traffic due to a multi-car accident on the highway. It was a heart-pounding moment, but thanks to our detailed backup plan, we were able to quickly source an alternative supplier and keep the project moving forward. That’s the power of thorough planning – it allows you to stay calm, cool, and collected, even when the unexpected strikes.

Mastering the Art of Concrete Team Coordination

Of course, planning is only half the battle when it comes to concrete projects. The other crucial element is your team – the skilled professionals who bring your vision to life. And let me tell you, coordinating all these moving parts is no easy task.

Think about it – you’ve got your project managers, site supervisors, concrete technicians, heavy equipment operators, and a whole host of subcontractors, all working in tandem to ensure a successful outcome. And each of these individuals brings their own unique expertise, priorities, and communication styles to the table. It’s like trying to choreograph a symphony, with every note and rhythm needing to be perfectly in sync.

That’s why effective team management is so critical in the world of concrete. It’s not enough to simply assemble a group of talented people – you need to cultivate a culture of collaboration, clear communication, and mutual accountability. As a project manager, I’ve found that regular check-ins, detailed task assignments, and open feedback channels are essential for keeping everyone on the same page.

And it’s not just about the internal team, either. Successful concrete projects also require seamless coordination with external stakeholders, from clients and regulatory bodies to material suppliers and subcontractors. By fostering strong relationships and aligning expectations, you can minimize the risk of misunderstandings, delays, and costly mistakes.

Remember that story I shared about the unexpected traffic incident? Well, that incident was a true test of our team’s cohesion and adaptability. But because we had built a culture of trust and open communication, we were able to spring into action and find a solution without missing a beat. That’s the power of mastering team coordination – it can make all the difference in the world of concrete.

Leveraging Technology to Optimize Concrete Projects

In today’s fast-paced, data-driven business landscape, technology has become an indispensable tool for mastering concrete projects. From cutting-edge design software to real-time project monitoring, the right digital solutions can mean the difference between a smooth, efficient endeavor and a chaotic, costly disaster.

Take, for example, the role of Building Information Modeling (BIM) in the world of concrete. By creating highly detailed, 3D digital representations of a project, BIM allows teams to identify potential clashes, optimize workflows, and make informed decisions long before a single cubic yard of concrete is poured. And with advancements in augmented and virtual reality, project managers can even “walk through” their construction sites, spotting issues and refining plans before stepping foot on-site.

But the technological revolution in concrete doesn’t stop there. Modern project management software, equipped with robust analytics and reporting capabilities, can provide unparalleled visibility into the progress, resource allocation, and financial health of a concrete project. And when you combine these digital tools with the power of the Internet of Things (IoT) – think smart sensors, drones, and automated equipment – the opportunities for optimization and efficiency are truly endless.

I’ll never forget the time we implemented a comprehensive IoT solution on a massive commercial high-rise project. By tracking material deliveries, equipment usage, and site conditions in real-time, we were able to identify and address bottlenecks before they snowballed into major delays. And the data we collected proved invaluable for future projects, helping us refine our processes and make more informed decisions.

Of course, harnessing the full potential of technology in concrete projects requires a certain level of digital fluency and a willingness to embrace change. But trust me, the payoff is well worth the effort. By leveraging the latest tools and solutions, you can not only streamline your concrete operations but also gain a crucial competitive edge in an increasingly tech-savvy industry.

The Power of Data-Driven Decision Making

In the world of concrete projects, data is the new gold. As project managers, we’re constantly bombarded with a deluge of information – from material costs and labor productivity to site conditions and quality control metrics. And the companies that can harness this data to drive their decision-making are the ones that truly come out on top.

Think about it this way – how can you possibly optimize your concrete processes if you don’t have a clear understanding of what’s working and what’s not? By diving deep into the numbers, you can uncover valuable insights that can help you identify bottlenecks, allocate resources more effectively, and make smarter, more informed choices.

And it’s not just about the data you collect during a project – it’s also about the insights you glean from past experiences. Business schools emphasize the importance of building a robust knowledge base, where you can draw on lessons learned, industry benchmarks, and best practices to inform your decision-making.

I’ll never forget the time we took on a complex residential foundation project, only to encounter a series of unexpected soil conditions that threatened to derail our timeline and budget. But by digging into our historical data, we were able to quickly identify a tested solution that had worked for us in the past. That not only saved us a ton of time and money, but it also gave us the confidence to tackle the challenge head-on.

Of course, data-driven decision making isn’t always easy – there’s a lot of noise to sift through, and it can be tempting to rely on gut instinct rather than cold, hard facts. But by cultivating a culture of analytical rigor and continuous improvement, you can transform your concrete projects from a series of guesses and gambles into a well-oiled machine, driven by data-backed insights and sustainable best practices.

Embracing a Flexible, Resilient Mindset

At the end of the day, the true secret to mastering concrete projects isn’t just about technical expertise or cutting-edge technology – it’s about mindset. You see, in this fast-paced, ever-changing industry, the ability to adapt and overcome is the difference between success and failure.

Think about it – concrete projects are inherently complex, with a million moving parts and a never-ending parade of potential curveballs. And the companies that thrive in this environment are the ones that cultivate a flexible, resilient mindset, willing to pivot and problem-solve on the fly.

As a project manager, I’ve seen it all – from sudden material shortages and weather-related delays to design changes and regulatory hurdles. And the key to navigating these challenges is to approach them with a calm, solutions-oriented attitude. It’s about embracing uncertainty, anticipating the unexpected, and having the courage to make tough decisions in the face of adversity.

But it’s not just about individual resilience – it’s also about fostering a culture of adaptability within your concrete organization. That means empowering your teams to think creatively, encouraging open communication, and building in plenty of wiggle room to account for the unexpected. Because let’s be honest, no matter how meticulously you plan, there’s always going to be something that throws a wrench in your concrete project. The companies that come out on top are the ones that are ready and willing to roll with the punches.

I’ll never forget the time we were working on a massive commercial project, and a critical piece of equipment broke down just days before the big concrete pour. It was a gut-wrenching moment, but thanks to our resilient mindset and strong team collaboration, we were able to quickly source a replacement, adjust our timeline, and deliver the project on time and on budget.

So, if there’s one key takeaway from this article, it’s this: Embrace the chaos, expect the unexpected, and never, ever lose your cool. Because in the wild, wild world of concrete, a flexible, resilient mindset is the superpower that can take your projects to new heights.

Conclusion: Elevating Your Concrete Game

Well, there you have it, folks – my hard-earned insights on mastering concrete projects through the lens of effective project management. From meticulous planning and team coordination to leveraging technology and embracing a resilient mindset, these are the essential elements that can help you elevate your concrete game and become an industry leader.

Of course, I know that implementing all of these strategies can seem like a daunting task, especially for those new to the concrete world. But the truth is, with the right mindset, the right tools, and the right team, there’s no challenge too great. And trust me, the payoff is more than worth it – not only in terms of successful, profitable concrete projects, but also in the sense of pride and accomplishment that comes with delivering top-notch results.

So, what are you waiting for? It’s time to roll up your sleeves, dive into the data, and start cultivating that flexible, resilient mindset. Because when it comes to concrete, the sky’s the limit, and I can’t wait to see what you and your team can accomplish.